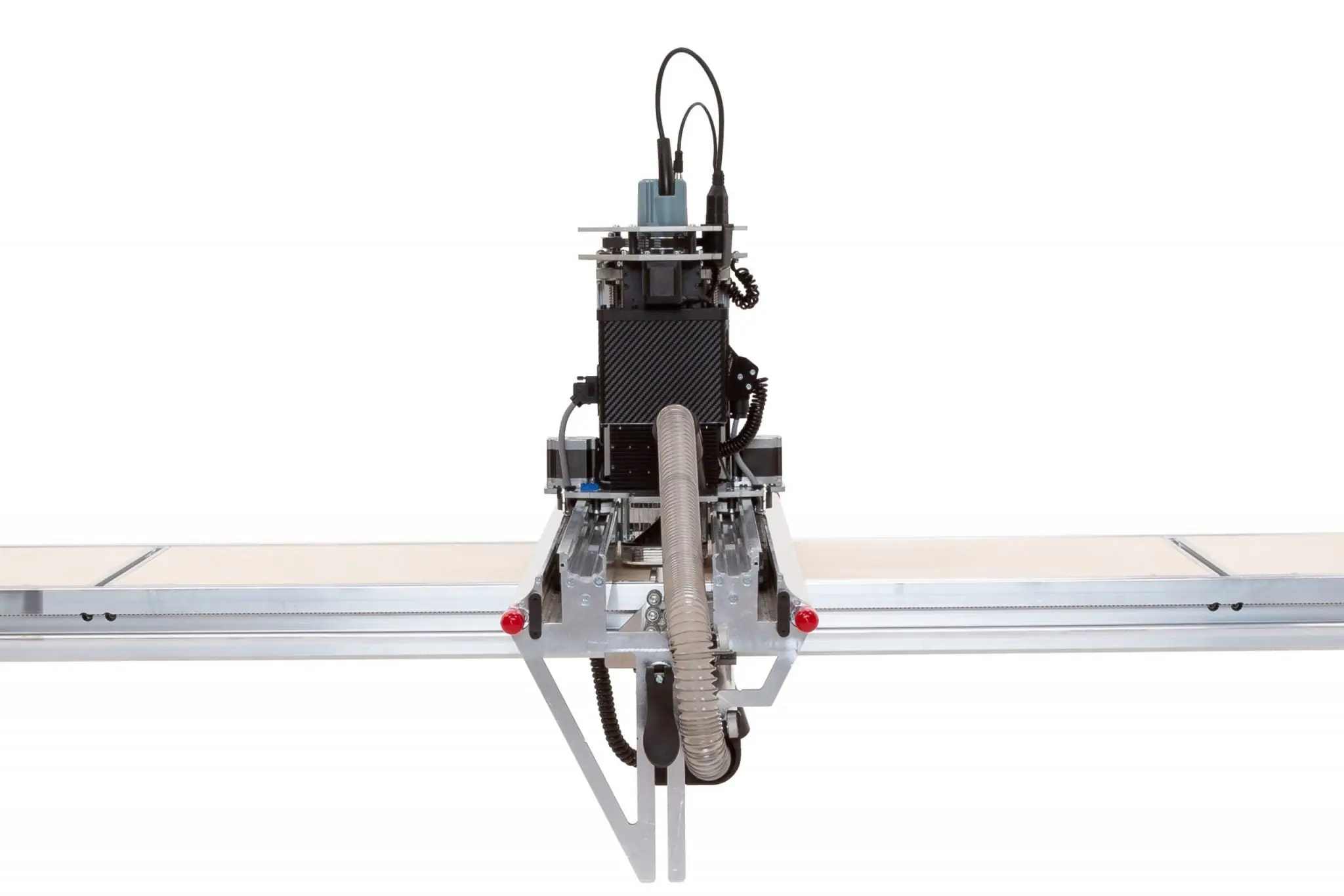

The Precision Pro, our flag ship large format CNC Router is the one for anyone who requires a higher degree of performance and accuracy from a CNC.

With all the excellent features of the SmartBench Precision, the Precision Pro comes with real time spindle load display giving you access to all the cutting information you need whilst running a job, an additional Lead screw to improve rigidity in the Z Axis, and a laser X/Y datum which makes setting a job start point quick and incredibly accurate.

Combined with ShapeCutter our new console based cutting app, you have an intuitive and powerful tool at your fingertips allowing you to start creating like never before.

For those new to CNC, ShapeCutter has a walk-through job wizard making getting started a simple process.

Features:

SmartBench PrecisionPro – Model Specific Features

- ZHead V3

- 230V 1000W Spindle

- Digital speed control

- Auto Tool Stop if spindle is in constant overload

- Real time spindle load display

- Precision ER16 collet – max 10mm shank

- Dual Z Axis Lead Screws for additional ridgidity

- Laser X/Y Datum set point system

- Can accommodate up to a 10 amp extraction system

ShapeCutter

- Easy to use step by step set-up wizard walks you through your cut.

- Navigation tabs allow you to navigate through the set up tasks.

- 10 different geometry types to choose from.

- Save your tool/job profile for a quick job turn around.

- Prompts and hints on process.

- Compatible with both inches and millimeters.

Ease of use

- Intuitive touch screen control.

- Wi-Fi (2.4GHz Network only)/USB connectivity for simple file transfer.

- Z Probe for fast, easy and accurate setting.

- Extraction system for clean operation.

- Pack up and store away in 3 minutes.

- Easy and quick calibration app ensures your SmartBench is always in tip top condition.

Improve efficiency

- Autonomous cutting – Working with you. SmartBench gets the job done whilst allowing you to get on with other tasks.

- Fast setup – plan your job on the touch screen, set your materials and press go.

- Astonishing job time – SmartBench can perform multiple cutting operations, dramatically improving your job time.

Portable

- SmartBench fits into a SWB van.

- Sections have been made to be handled by one person.

- Nothing more required to start producing standard shapes than SmartBench and a router bit.

- Set up on site within 3 minutes.

- Height adjustable feet makes light work of setting up on un-even surfaces.

Big capabilities

- Process up to 2500mm (98.43”) x 1250mm (49.2”) sheets edge to edge.

- Use SmartBench in feed-through mode and process any length of work surface.

Multi materials

- Softwood and hardwood timber sections up to 150mm thick.

- Timber based composite boards

- Composite worksurfaces

- Polycarbonate, Acrylic and other forms of plastic

Quality and accuracy assured

- Accuracy of +/-0.5mm or better

- CE certified

- Remote software upgrades means you get the benefit of our ever increasing library of cutting apps

Safety in mind

- E Stop

- Interupt bars along the x axis

- Cutter door open cut out switch

What else do you need?

CAD/CAM software

In order to get cutting, you’ll need to use your own CAD/CAM software to design and create your projects. We recommend Vectric software or Autodesk’s Fusion 360 to model and CAM process your files. Fusion is free to makers, education and small businesses.

Other G Code generating CAD/CAM packages can be used.

Router bits

Standard router bits can be used to fit the router head

Extraction

You will need to provide an extraction unit to attach our standard hose to, and then plug the power supply into the on/off socket provided.