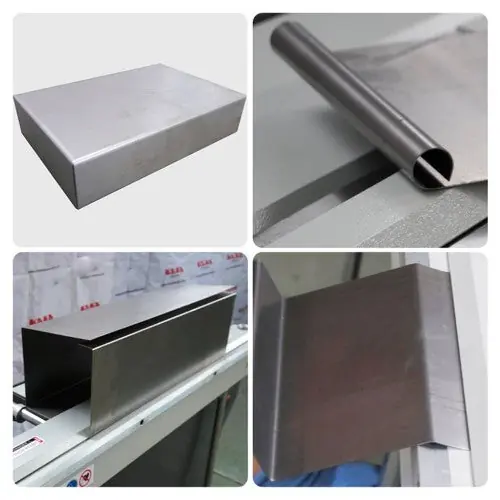

A magnetic brake from Oltre X JDC Bend lets you make enclosed shapes that would be impossible on traditional metal brakes. You can bend steel, aluminum, copper, and plastic, among other materials. Open up almost unlimited possibilities! This sheet metal brake can bend boxes or pans to almost any depth since it doesn’t rely on conventional finger depths. Runs on 240V single phase power and will work at virtually any site. 1250mm length with a maximum capacity of 16 gauge mild steel. The breakthrough open-ended design allows you to create enclosed ducts and shapes impossible to make with a traditional box and pan brake. 6 tonne magnetic power is consistent across the entire beam, allowing for crisp bends even in the middle of the brake. Scaled stroke angle control lets you deliver repeatable bends time after time. You can set up the mild steel clamping bar with straight bars (of various widths if you had very tight boxes to make) for straight bends or segmented clamping bars for box and pan applications. Blade gap adjustment on the clamping bars lets you work with sheet metal of different thicknesses. You can remove the bottom leaf’s bending extension for the tightest bend dimension between bends of .625″.

Each electromagnetic sheet metal brake from Oltre offers

- Open-ended design: The open top gives you the flexibility to make any kind of bend imaginable, including enclosed boxes or triangles.

- Magnet with 6 tonne of force – The powerful magnet holds the material in place so that you can clamp it within the open concept design.

- Foot pedal or push-button controls – Engage the magnet and leave your hands free to guide the material.

- Small footprint: This do-it-all machine doesn’t take up much space in your shop.

Recommended for

- HVAC shops, industrial art shops, and general sheet metal fabrication shops.

- Making ductwork, triangles, alternate bends on varying planes, round items such as scrolling applications, and much more.

Easy, hands-free operation

- Put a piece of material between the clamping bar to the depth required.

- Engage the powerful magnet in the bending bed with push-button control.

- Hit the foot pedal that softly clamps the material. This foot control keeps your fingers safely out of the machine and you to reposition the material.

- Lift the bottom bending leaf to complete the bend.

Technical Data

Customer Testimonial

Options

- OT-MB-1250E

- JDC1250ED+SHEAR